Get our independent lab tests, expert reviews and honest advice.

How we test kitchen knives

Every home needs a good-quality kitchen knife. The repetitive act of smooth, seamless slicing is easy with a well-made knife, whereas a poorly made knife will require a lot more effort and won’t hold its sharpness as well.

On this page:

But with prices ranging from less than $10 to $400 or more, it can be hard to cut through the marketing fluff to find the right balance of price and performance. Is a $299 knife really better than one that costs $50, or does the cheaper one work just fine?

This is how we answer those questions, and more, with our 20cm kitchen knives test.

How we choose what we test

We test 20cm cook’s and chef’s knives from a variety of manufacturers and countries, including Japan and Germany.

We look for knives available at a range of price points, starting with affordable models widely available in supermarkets and major retailers. We also buy expensive knives sold only in specialty stores, kitchen and homeware retailers and online.

The aim is to buy knives from popular, easily identifiable brands or models sold exclusively through popular retailers. We also typically add one or two lesser known brands to the test where we can.

We buy two of each knife – one for cutting performance tests and one for the knife sharpness and edge retention tests. That way the knives are assessed out of the box as opposed to being partly worn down from a previous part of the test.

How we test kitchen knives

Our kitchen knives test is made up of two components:

- Cutting performance conducted in house by our test experts.

- Knife sharpness and edge retention tested in partnership with the University of New South Wales (UNSW).

We also conduct an ease of use assessment with left and right-handed volunteers in-house, to prepare good and bad points and a general summary of how it feels to use each knife.

Cutting performance

Our testers slice a variety of vegetables and one type of meat to assess cutting performance:

- Tomatoes (full slices)

- Carrots (julienne)

- Onions (half-moon slices)

- Steak (diced)

Our testers look for clean, evenly cut slices with little resistance from the blade.

These test contribute equally to the cutting performance score (25% each).

Knife sharpness and edge retention

We partnered with the University of New South Wales to conduct a sharpness and edge retention test. The test is carried out over two main parts: a cut depth test to assess the knives sharpness, and a burnishing process to simulate wear and dulling of the knives.

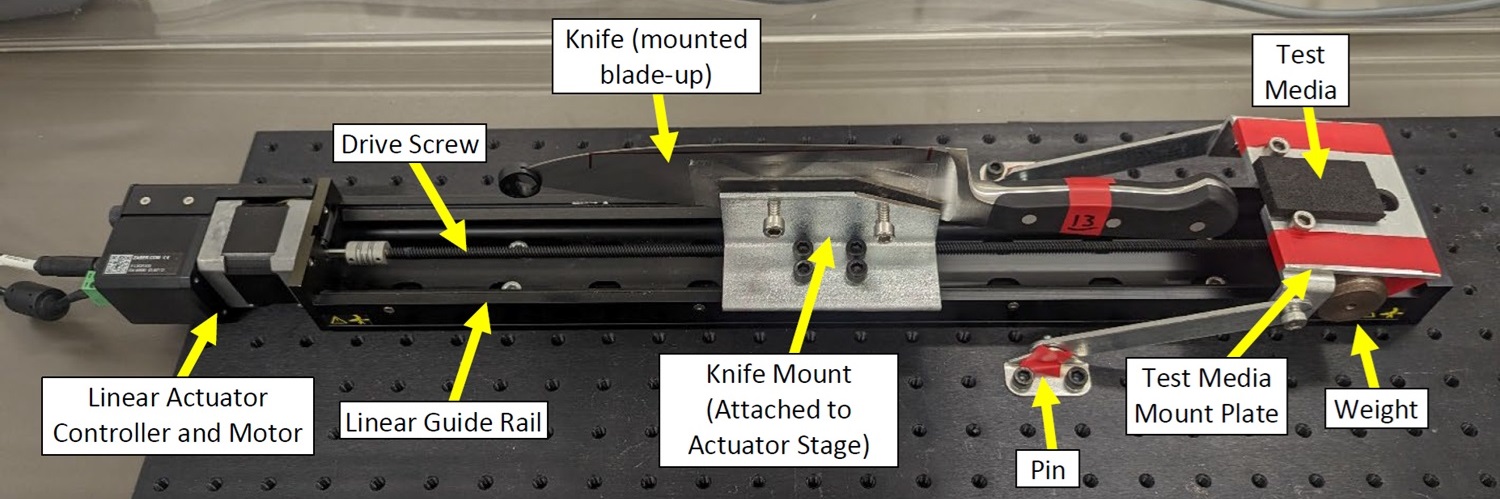

These tests are conducted with a mechanical rig for consistency and safety.

The initial sharpness and final sharpness are used to generate the sharpness score.

Knives that maintain a greater depth of cut after burnishing are considered to have better edge retention, as they are more resistant to the wear and dulling induced by the burnishing process.

Initial cut depth

Each knife is mounted on an actuator stage with a constant load of 760 grams applied for the cut. Ethylene-vinyl acetate foam is mounted in place for the blade to slice through. This is used due to its high homogeneity, which ensures consistent results throughout the testing process.

The linear actuator moves the knife at a rate of 20 millimetres per second to cut into the foam, for a total distance of 150mm. Then the depth of the cut is measured. A deeper cut indicating a sharper knife, as it can more easily penetrate the test media under a constant load and slice length.

Burnishing process

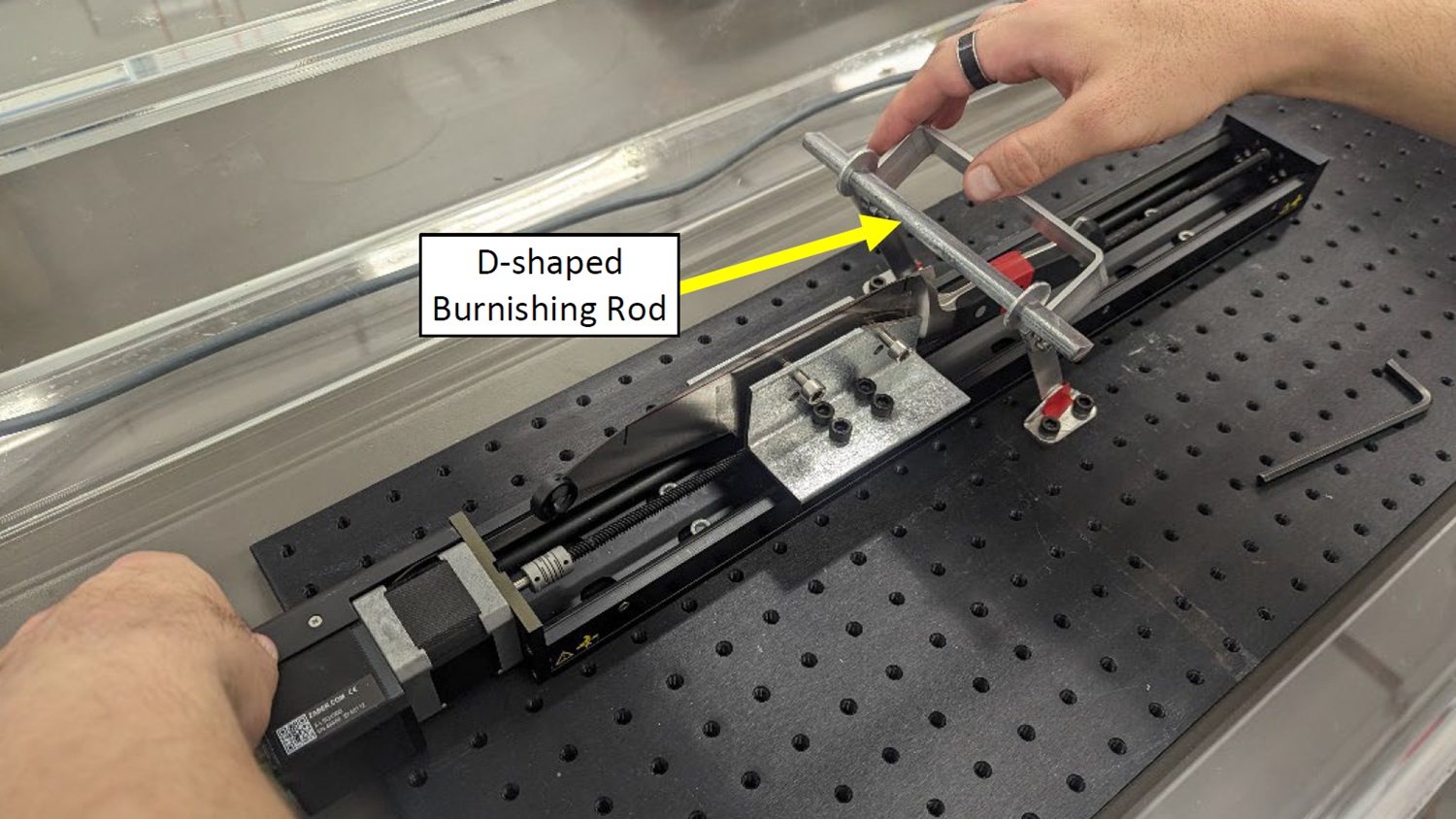

This simulates wear and dulling that occurs during normal use (for example, chopping vegetables). The knife is mounted on the same actuator stage then run along a D-shaped, 12mm galvanised steel rod at a constant load of 150 grams. This moves the knife through 50 burnishing stroke cycles, with stroke lengths of 160 mm.

Repeating the process

Each knife is subjected to three cut depth tests with two 50-cycle burnishing processes in between them. This allows for a comparison of the knife’s performance at three points: initial sharpness, after 50 burnishing strokes, and after 100 burnishing strokes.

Test criteria explained

The CHOICE Expert Rating is made up of:

- Cutting performance score: 70%

- Sharpness score: 30%

The Sharpness score is made up of:

- Initial sharpness (30%)

- Final sharpness after 100 strokes (70%)